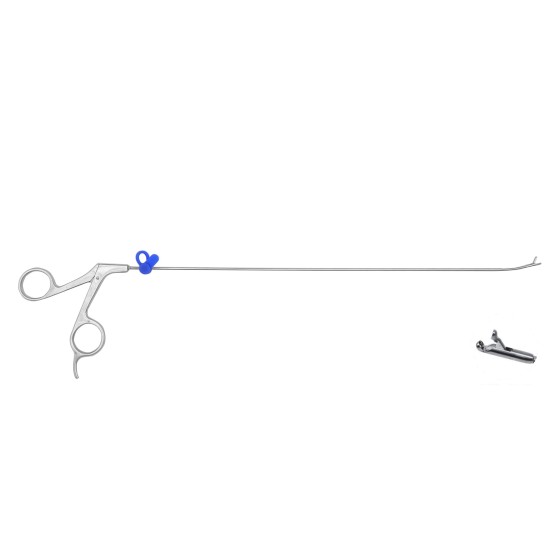

The core value of QuNamai's specialized arthroscopic surgical instrument (duckbill-shaped straight blue forceps, specification: 3.2mm × 120mm) in clinical practice. The instrument is made of medical-grade stainless steel, and its design core lies in the integration of an ergonomic handle that fits the hand shapes of doctors in Asia, Europe, and the Middle East with an efficient mechanical lever system. By analyzing its material properties, biomechanical design, and morphological parameters, this study demonstrates its key role in achieving precise, efficient, and low-fatigue operations in arthroscopic surgery, thereby providing reliable hardware support for improving surgical success rates and surgeon comfort.

Keywords: Arthroscopic surgical instruments; Ergonomics; Biomechanics; Medical stainless steel; Blue forceps; QuNamai

The success of arthroscopic surgery, a minimally invasive surgical technique, highly depends on efficient and precise interaction among the "surgeon-instrument-patient" triad. Among these, the performance of surgical instruments is a key factor limiting surgical precision and efficiency. Traditional instruments often have issues such as poor handle feel, 费力 operation, and mismatch with the surgeon's hand, leading to surgeon fatigue and subsequent impact on surgical outcomes. To address this pain point, QuNamai has launched a series of meticulously designed arthroscopic instruments. Taking one of its representative products—the duckbill-shaped straight blue forceps (3.2mm × 120mm)—as an example, this article will deeply analyze the significant advantages of its innovative design in arthroscopic surgery from the perspectives of materials science, biomechanics, and design morphology.

The main body of the instrument is made of medical-grade stainless steel (usually 316L or martensitic stainless steel). The selection of this material is based on its multiple core advantages:

-

Superior biocompatibility: It complies with standards such as ISO 7153/ ASTM F899, ensuring its inertness and safety in the human internal environment, with no risks of toxicity, sensitization, or carcinogenicity. It can withstand repeated high-pressure steam sterilization without corrosion.

-

High mechanical strength and wear resistance: It can withstand repeated cutting operations and lever forces, ensuring that the jaw (duckbill-shaped design) remains sharp-edged and accurately aligned even after long-term use, avoiding tissue slippage or tearing due to wear.

-

Appropriate weight and texture: It provides the instrument with 恰到好处的 counterweight, enhancing the surgeon's operational stability and handle feedback, which is the physical basis for achieving precise control.

The design of QuNamai's handle goes beyond adapting to a single regional population; its innovation lies in comprehensively considering the big data on hand size of doctor groups in Asia, Europe, and the Middle East. This means:

-

Handle contour and curvature: Optimized to naturally fit the grip curve of palms of different sizes, achieving tension-free full-hand grip.

-

Finger ring size and spacing: Scientifically distributed to allow operation with gloves while providing stable fulcrums and comfortable force-exerting space for fingers, effectively preventing finger joint strain caused by long-term operation.

-

Surface treatment: Usually adopts matte or special texture treatment to provide sufficient friction even in a wet surgical environment, preventing slippage and ensuring absolute reliability of control.

"顺畅 cutting due to mechanical lever design" is the technical essence of this instrument. Its internal transmission mechanism undergoes precise calculation:

-

Optimized fulcrum position: The fulcrum is set at the optimal force arm ratio position, enabling the surgeon to generate maximum cutting force (output force) at the jaw with minimal finger force (input force).

-

Low-friction transmission: Internal joints are processed and polished with high precision to minimize internal friction loss, making force transmission efficient, direct, and the handle feel clear and "smooth".

-

Labor-saving effect: This design significantly reduces the muscle load required to complete actions such as cutting and grasping, greatly alleviating the surgeon's fatigue during long-term, high-precision surgeries, which is particularly crucial for ensuring the success of complex surgeries.

-

Diameter of 3.2mm: It is compatible with standard arthroscopic working channels, allowing flexible movement within most joints (knee, shoulder, ankle, etc.), balancing operational strength and minimal invasiveness.

-

Length of 120mm: This length provides an ideal operating lever, ensuring accessibility to deep joint cavities (such as the posterior knee joint space) while avoiding tremor or control delay caused by excessive length.

-

Duckbill-shaped straight design: The "duckbill-shaped" jaw provides a large occlusal area and a unique angle, which is very suitable for efficiently resecting, grasping, and removing soft tissues such as meniscal fragments, loose bodies, and hypertrophic synovium. The "straight" design provides excellent directivity and convenience for linear operation, making it the most basic and widely used instrument shape in arthroscopic surgery.

Integrating the above designs, the instrument plays the following core roles in arthroscopic surgery:

-

Enhancing surgical precision: Excellent handle feedback and stable controllability enable surgeons to achieve millimeter-level precise operations, accurately resecting diseased tissues and protecting healthy structures.

-

Improving surgical efficiency: Smooth cutting ability and strong grasping force make tissue processing fast and efficient, shortening surgical time, thereby reducing the patient's anesthetic risk and infection probability.

-

Enhancing surgeon endurance: The global ergonomic design and labor-saving lever system effectively delay muscle fatigue, allowing surgeons to maintain a high level of operational stability during long-term surgeries, which is crucial for ensuring the success of complex surgeries.

-

Ensuring surgical safety: Reliable material performance and precise manufacturing processes eliminate extreme risks such as instrument breakage in the body and residual debris, ensuring patient safety.

QuNamai's arthroscopic blue forceps is by no means a simple tool manufacturing, but a product of the in-depth integration of materials science, ergonomics, biomechanics, and clinical medicine. Its medical-grade stainless steel ensures safety and durability; the **handle design based on global multi-regional data achieves extreme surgeon adaptation and comfort; the optimized mechanical lever system brings unparalleled "smooth cutting" operation experience. Finally, these advantages converge on the 3.2mm × 120mm duckbill-shaped straight type with 恰到好处的 specifications, making it a reliable, efficient, and humanized key tool for treating soft tissue lesions under arthroscopy. It represents an important trend in the development of modern sports medicine instruments towards more precision and humanization.